No Result Found!

TRENDING SEARCHES

Recently Viewed

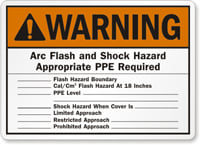

Sharks are among the most aggressive ocean predators at sea. The great white shark ranks number one as the most dangerous sea creature, and the species as a whole ranks number eight as the most dangerous animal. Nonetheless according to Fire Engineering Magazine, injuries from arc flashes, a type of electrical explosion resulting from an alternating current, occur more than 1,000 times as often as shark attacks do! With 10 accidents occurring each week, two of which are usually fatal, arc flash occurrences are nothing to scoff at. The injuries and damages from arc flashes are endless including hearing loss, eyesight loss, memory loss, lung collapse, and burns-even from just from the light and heat admitted from electric currents. While signs do not exclusively prevent arc flashes from occurring, Arc Flash Warning Signs alert workers of the dangers involved and inform them of the necessary safety precautions.

Sharks are among the most aggressive ocean predators at sea. The great white shark ranks number one as the most dangerous sea creature, and the species as a whole ranks number eight as the most dangerous animal. Nonetheless according to Fire Engineering Magazine, injuries from arc flashes, a type of electrical explosion resulting from an alternating current, occur more than 1,000 times as often as shark attacks do! With 10 accidents occurring each week, two of which are usually fatal, arc flash occurrences are nothing to scoff at. The injuries and damages from arc flashes are endless including hearing loss, eyesight loss, memory loss, lung collapse, and burns-even from just from the light and heat admitted from electric currents. While signs do not exclusively prevent arc flashes from occurring, Arc Flash Warning Signs alert workers of the dangers involved and inform them of the necessary safety precautions. The Safety and Health Assessment and Research for Prevention warns of the potential dangers from arc flashes in unsafe environments. A worker in Washington sustained burns to over 20% of his body after his shirt caught on fire from the force of an arc blast. Another man, with over 20 years of experience as an electrician, de-energized the wrong circuit, causing an arc flash that burned his arm, neck and face. A third worker endured electric shocks to his leg and accompanying flash burns to his body while holding an energized wire that grounded through his leg. Unfortunately some employers don’t appreciate the gravity and potential dangers of arc flashes enough to implement necessary safety procedures. In order to prevent accidents such as those detailed above, install Arc Flash Danger Signs which list safety precautions for work places involved with electricity. The Safety and Health Assessment and Research for Prevention has gone so far to report that “No worker has ever been injured or killed by an arc flash while working in an Electricity Safe Working Condition.

The Safety and Health Assessment and Research for Prevention warns of the potential dangers from arc flashes in unsafe environments. A worker in Washington sustained burns to over 20% of his body after his shirt caught on fire from the force of an arc blast. Another man, with over 20 years of experience as an electrician, de-energized the wrong circuit, causing an arc flash that burned his arm, neck and face. A third worker endured electric shocks to his leg and accompanying flash burns to his body while holding an energized wire that grounded through his leg. Unfortunately some employers don’t appreciate the gravity and potential dangers of arc flashes enough to implement necessary safety procedures. In order to prevent accidents such as those detailed above, install Arc Flash Danger Signs which list safety precautions for work places involved with electricity. The Safety and Health Assessment and Research for Prevention has gone so far to report that “No worker has ever been injured or killed by an arc flash while working in an Electricity Safe Working Condition. Over 80% of injuries in an electrically pervasive environment are the handiworks of arc flashes. People working with energized equipment are constantly at risk of electric shock and explosions. Nonetheless, a few conditions such as dropped tools or other gear with sparks, gaps in insulating materials, and inadequately installed or maintained equipment increase the chances of potential risks. Self-laminating enhanced Arc Flash Warning Labels that allow you to customize the electricity and voltage details of your work lab can help keep the risks to a minimum. The NFPA 70E-2000, Standard for Electrical Safety Requirements for Employee Workplaces, advises companies to follow the federal compliance actions for safe work practices. The OSHA, Occupational Safety and Health Administration, which enforces safety standards and cites to the NFPA safety requirements, endorses warning labels, proper tools, training for workers, personal protective equipment (PPE), and calculations of the degree of arc flash hazard. Arc Flash Labels in both durable economy vinyl and economy paper which detail the NFPA requirements and endorse PPE facilitate establishing a cautious work environment.

Over 80% of injuries in an electrically pervasive environment are the handiworks of arc flashes. People working with energized equipment are constantly at risk of electric shock and explosions. Nonetheless, a few conditions such as dropped tools or other gear with sparks, gaps in insulating materials, and inadequately installed or maintained equipment increase the chances of potential risks. Self-laminating enhanced Arc Flash Warning Labels that allow you to customize the electricity and voltage details of your work lab can help keep the risks to a minimum. The NFPA 70E-2000, Standard for Electrical Safety Requirements for Employee Workplaces, advises companies to follow the federal compliance actions for safe work practices. The OSHA, Occupational Safety and Health Administration, which enforces safety standards and cites to the NFPA safety requirements, endorses warning labels, proper tools, training for workers, personal protective equipment (PPE), and calculations of the degree of arc flash hazard. Arc Flash Labels in both durable economy vinyl and economy paper which detail the NFPA requirements and endorse PPE facilitate establishing a cautious work environment.